- Home Page

- Company Profile

-

Our Products

- Pulp And Paper Machinery And Parts

- Cardboard Machinery And Parts

- Mineral Processing Equipment And Parts

- Insulation Materials And Felts

- Corugated packaging machine and parts

- Wire Mesh

- Contact Us

Specialized Forming Fabric For Cresent Paper Machine

20 USD ($)/Square Meter

Product Details:

X

Specialized Forming Fabric For Cresent Paper Machine Price And Quantity

- 20 USD ($)/Square Meter

- 10 Square Meter

- 20.00 - 50.00 USD ($)/Square Meter

Specialized Forming Fabric For Cresent Paper Machine Trade Information

- Tianjin, Beijing, Shanghai

- 500 Square Meter Per Month

- 20 Days

- Yes

- Free samples are available

- Wooden Box. Standard Export Package.

- All India

Product Description

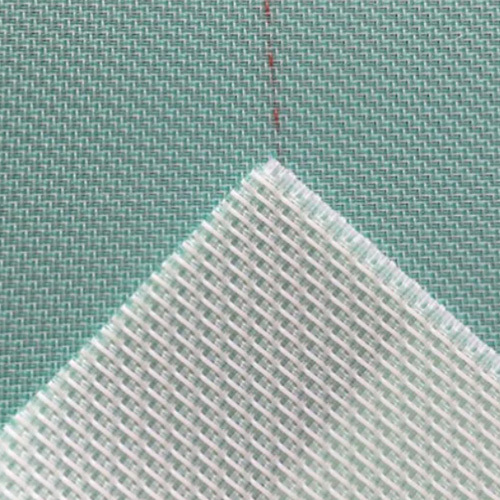

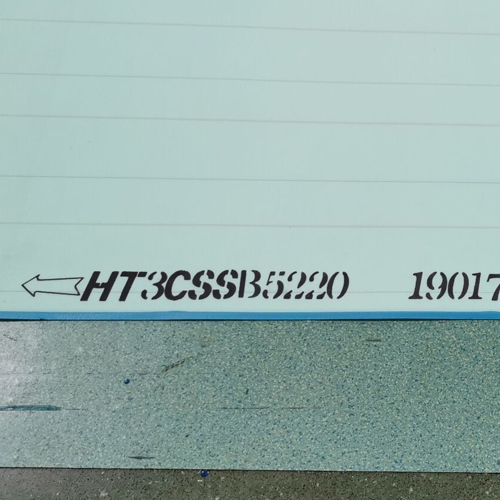

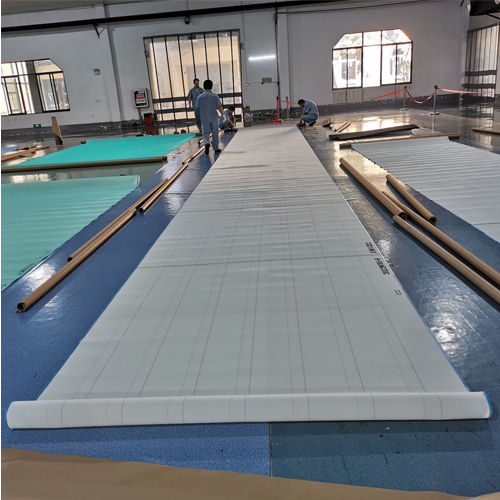

Specialized Forming Fabric For Cresent Paper Machine

Designed Specifically for Cresent Former Tissue Paper Machine

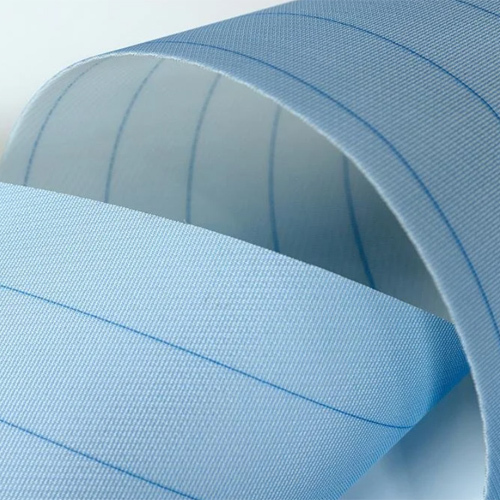

With a unique design, Huatao was developed to help tissue-makers increase their productivity and performance. The combination of "High Fiber Support" and "High Drainage Capability" offered by the cresent former forming fabric is reflected in benchmark performances on over 100 high speed tissue machines worldwide. It also offers improved sheet formation by reducing both "Pin Holes" and "Fiber Carry Back". For these reasons, Huatao's cresent former forming fabric has received high accolades from many customers.

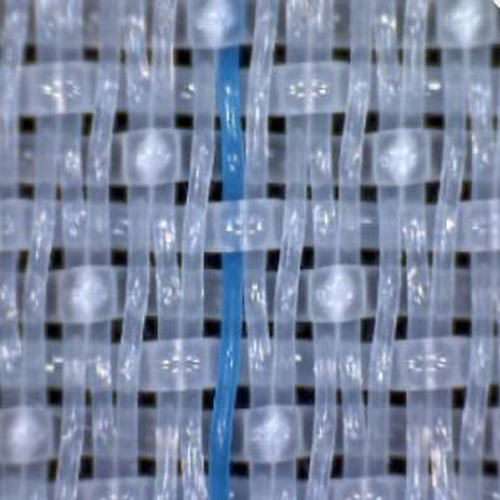

Crescent Formers is the ultra-fast formation of the sheet. As the furnish is injected via the headbox, the impingement is captured and formed in the fabric instantaneously. Within this ultra-fast forming process, critical sheet quality properties, such as formation, tensile strength, and porosity, must be developed. Huatao's research team reveals that the ideal forming fabric for high-speed machines should provide two performance-specific attributes "Very High Fiber Suppor" and "High Drainage Capability under hydraulic load".

Better Drainage

Achieving better drainage is Huataos' top priority throughout its design processes. In this design, the warp is used as the binding yarn that brings together the sheet side and machine side layers. Because of this weave structure, the design offers immense flexibility to improve sheet side mesh structure and yarn diameter which are critical to ensuring the required grade and property. In a common SSB (Shute Supporting Binder) type triple-layer design, by contrast, the weft is used as the binding yarn between sheet side and machine side layers.

Enter Buying Requirement Details