- Home Page

- Company Profile

-

Our Products

- Pulp And Paper Machinery And Parts

- Cardboard Machinery And Parts

- Mineral Processing Equipment And Parts

- Insulation Materials And Felts

- Corugated packaging machine and parts

- Wire Mesh

- Contact Us

Polyester Plain Woven Filter Fabric Belt

2000 USD ($)/Piece

Product Details:

X

Polyester Plain Woven Filter Fabric Belt Price And Quantity

- 10000.00 - 40000.00 USD ($)/Piece

- 2000 USD ($)/Piece

- 1 Piece

Polyester Plain Woven Filter Fabric Belt Trade Information

- Tianjin, Shanghai, Beijing

- 500 Piece Per Month

- 30 Days

- Yes

- Free samples are available

- Wooden Box. Standard Export Package.

- All India

Product Description

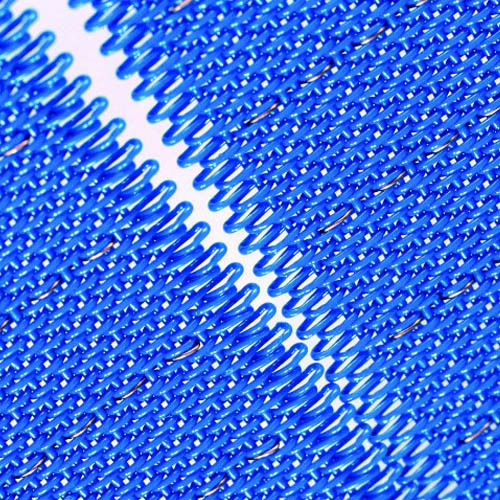

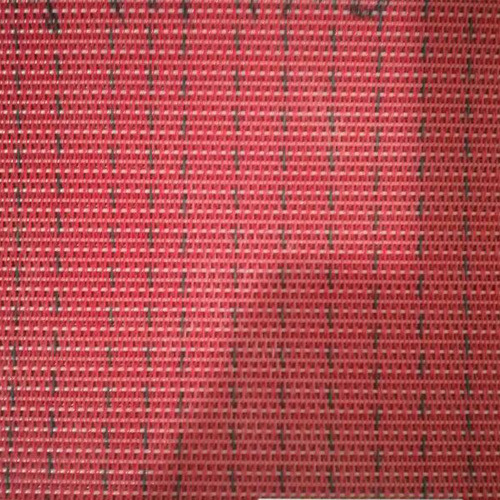

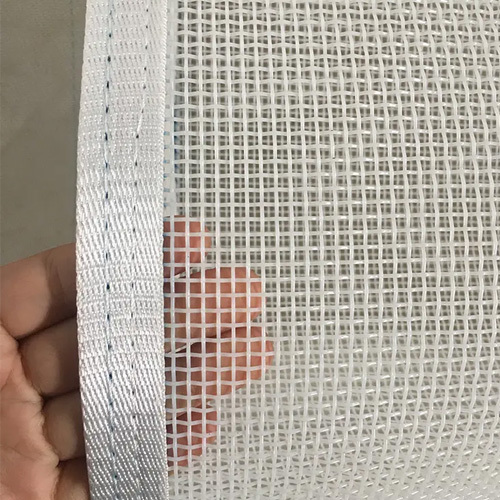

Polyester Plain Woven Filter Belt

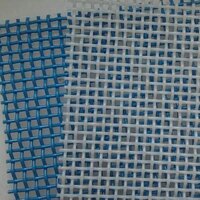

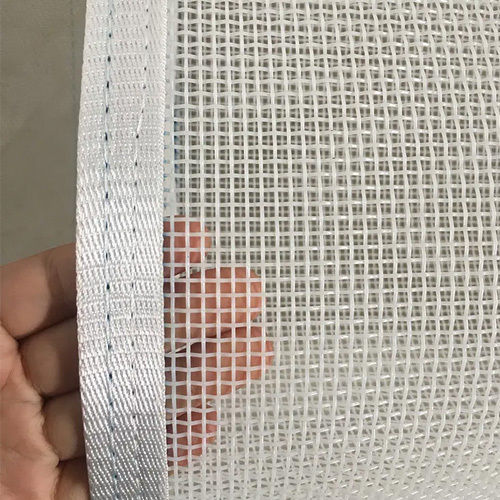

Also named linear screen cloth, plain woven belt, polyester mesh belt.

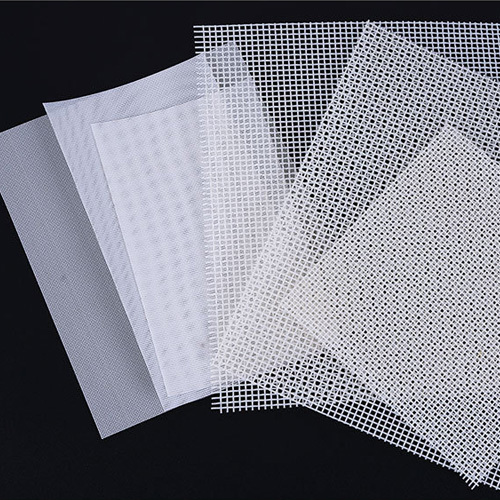

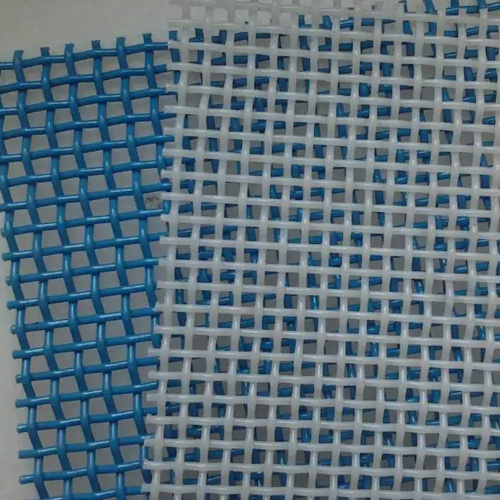

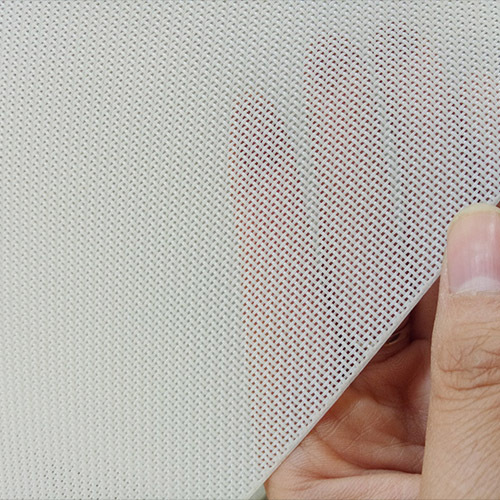

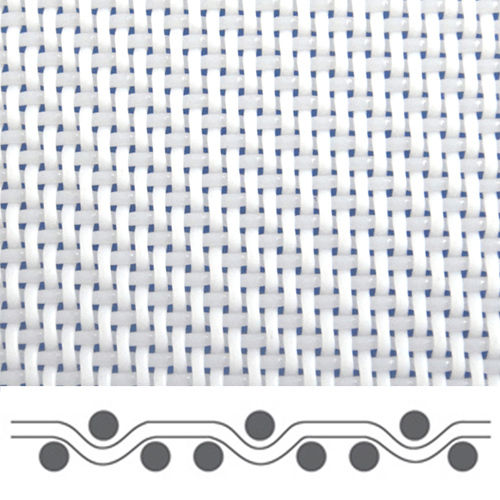

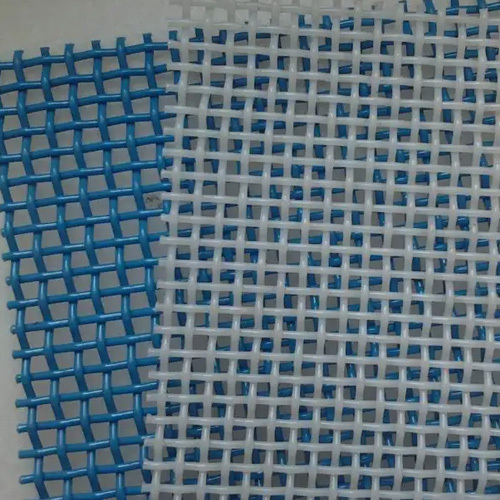

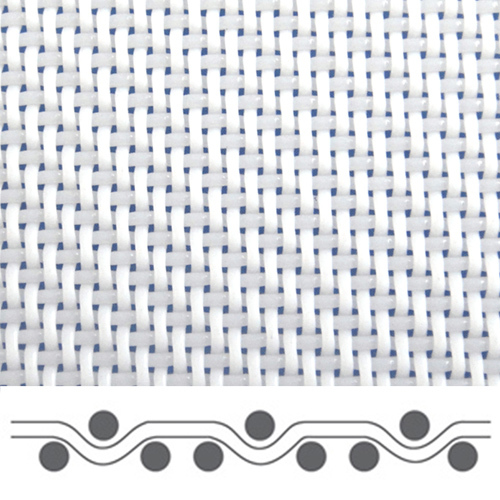

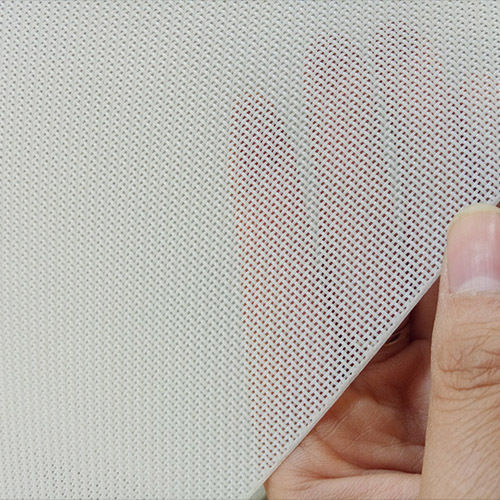

The polyester plain filter fabrics are also called linear screen cloth or polyester mesh conveyor belts. The weaving pattern is 2-shed and 3-shed available in various meshes, caliper, GSM, and air permeability for different applications. They are widely used in various industries as dryer fabrics, conveyor belts, filter cloths, and food & vegetable drying.

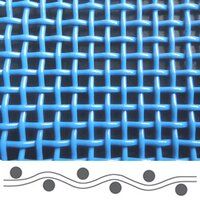

Weaving Type: 2-shed & 3-shed

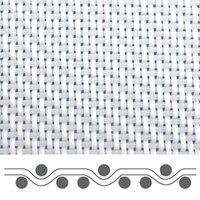

2-Shed Polyester Plain Woven Fabric, its structure is Plain Weave Structure.

Filter fabrics with the 2-shed plain weave have high weave stability and predefined uniform size of apertures, so they can also be used to sort particles according to their size on linear screen separators.

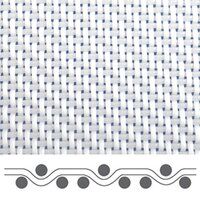

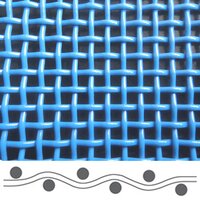

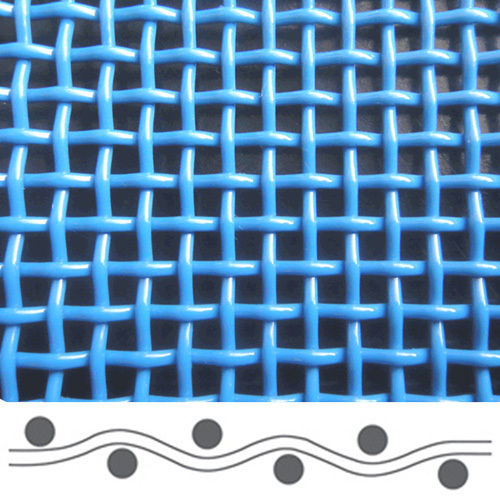

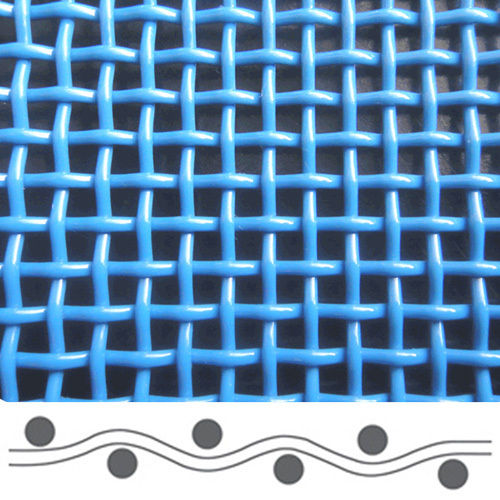

3-Shed Polyester Plain Fabric, its structure is Twill Weave Structure.

Filter fabrics with the three-shaft twill weave have a very high dewatering ability and a higher wear resistance than fabrics with the plain weave.

Application

1. Pulp board making.

2. Wood industry: Dryer belts of woodchips, particle boards, MDF/HDF, etc.

3. Nonwoven cloth industry.

4. Food drying.

5. Material screening and separation.

6. Environment protection: sludge dewatering in belt press filters.

7. The pre-cleaning process before fruit and vegetable processing.

Enter Buying Requirement Details