- Home Page

- Company Profile

-

Our Products

- Pulp And Paper Machinery And Parts

- Cardboard Machinery And Parts

- Mineral Processing Equipment And Parts

- Insulation Materials And Felts

- Corugated packaging machine and parts

- Wire Mesh

- Contact Us

Hot plate belt

130 USD ($)/Square Meter

Product Details:

X

Hot plate belt Price And Quantity

- 1 Square Meter

- 130 USD ($)/Square Meter

Hot plate belt Trade Information

- Beijing,Tianjin,Shanghai

- Western Union Paypal Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T)

- 50000 Square Meter Per Year

- 20 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- wooden box or plastic bag

- Australia North America South America Eastern Europe Western Europe Middle East Central America Asia Africa

- All India

- IOS

Product Description

Hot plate belt

The corrugated board conveyor belt is one of the most important parts of the corrugated board production line. Its quality has a decisive influence on the quality of corrugated cardboard. Conveyor belts are usually used on fully automatic tile lines.

The role of conveyor belt:

Connect and provide tension

Transfer cardboard

Conduction pressure

Moisturizing and removing dampness

Type:

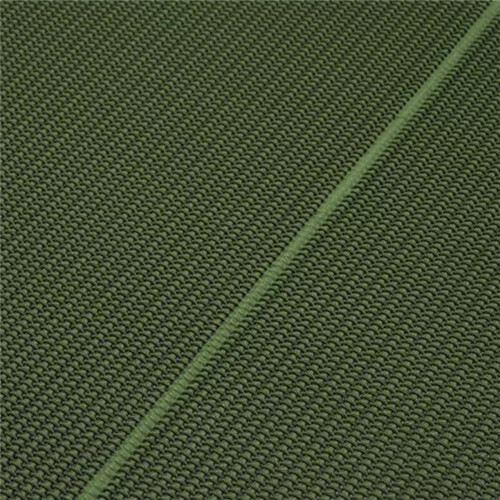

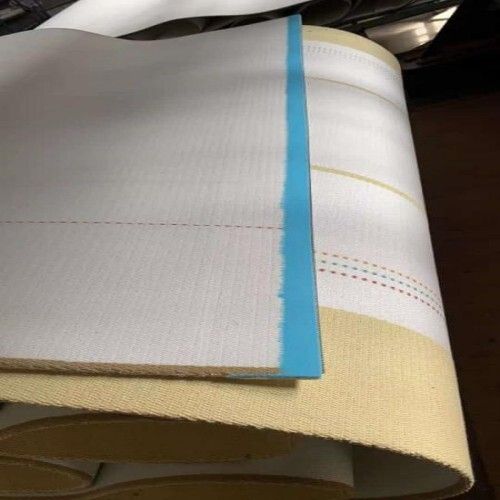

1.Woven corrugator belt: The Woven corrugator belt is woven from polyester synthetic long fibers. The Woven corrugator belt is designed and manufactured to adapt to the high-speed operation of the corrugated machine. Its unique structure and high performance polyester fiber material effectively meet the moisture absorption and dehumidification of cardboard under the conditions of running at a speed of more than 200 meters to ensure the quality of the cardboard. At the same time, the braided layer on the surface effectively reduces the noise and improves the surface friction coefficient.

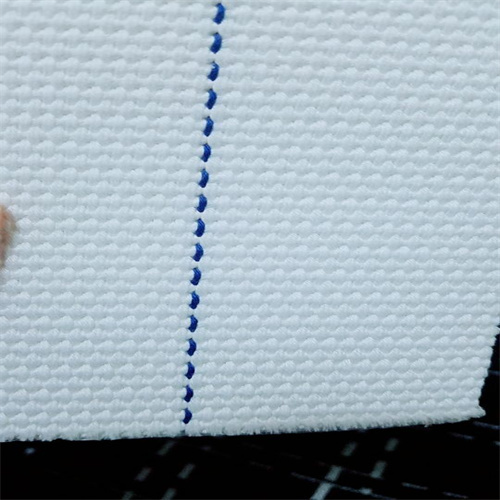

1)Corrugator belt with kevlar ege: a kind of braided conveyor belt. The reinforced high speed belt is a further upgrade of the ordinary high-speed belt. It is suitable for corrugated paper machines in high-speed operation conditions, and is well suited for frequent changes in cardboard width and load changes. The edge reinforcement is made of ultra-abrasive and high tensile Kevlar, which increases the wear resistance and longevity of the straps.

There are two types of joints for braiding conveyor belts:

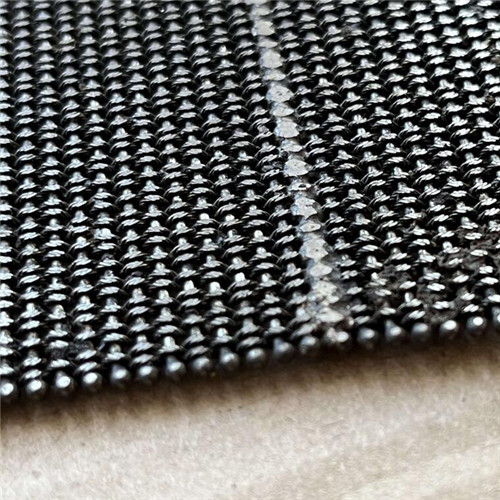

1) Hot Jaw lacing joint: The Hot Jaw lacing joint adopts high temperature and static pressure method to carry out special treatment on the tile wire conveyor belt, and then uses advanced equipment to install steel hooks. Then use high temperature resistant fluff material to stick to the belt joint and steel hook. This process protects the fiber material on the belt surface and will not reduce the tensile force of the belt itself. The fluff treated joint has a smooth surface, no noise, cardboard No indentation on the surface.

2) Rubber coated joints: Rubber coated joints use high temperature static pressure to process the joint parts, and then use an advanced hooking machine to fix the steel hooks firmly (imported American sailing steel buckles) and then use a unique process to resist high temperature. And wear resistant rubber is filled into the joint of the belt, which not only ensures the tensile strength and wear resistance of the belt, but also improves the service life of the belt, reduces the running noise, and improves the flatness of the cardboard surface.

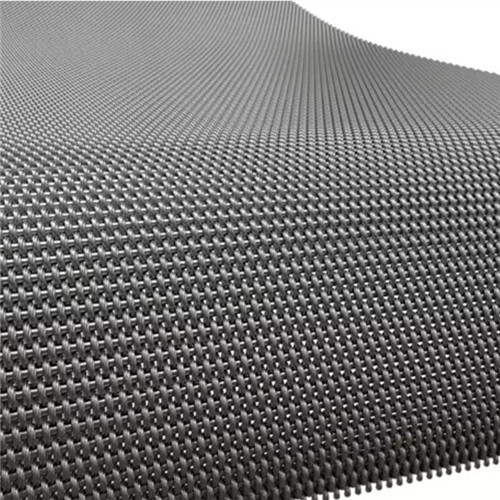

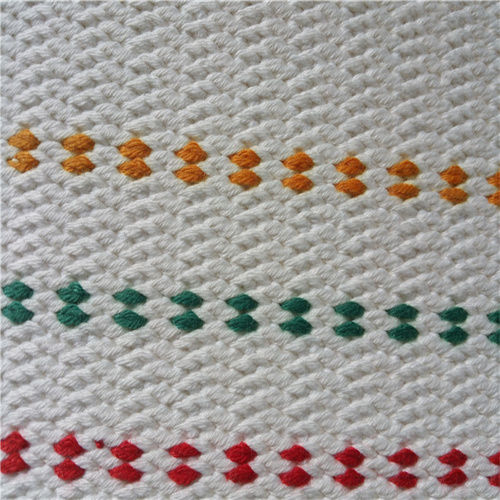

2.Needle corrugated belt: Needle corrugated belt adopts unique non woven needle punching technology and advanced production technology. The cloth is the middle layer, and after repeated multiple acupuncture processes. It is successfully manufactured after high temperature setting and chemical treatment.

1) No dipping agent (basic type)

2) Single sided dip

3) Double sided dipping agent, and wear-resistant agent 10 to 15cm can also be added on both sides (the ingredient of the dipping agent is Teflon, which ensures the stiffness and wear resistance of the belt, on the equipment side, not next to the cardboard side)

Needle corrugated belt often have hidden joints.

Features:

High temperature resistance

Anti aging

flat surface

Dimensionally stable

Adapt to high speed less than 300m/min

Long life 50 to 60million linear meters running at 150m/min speed

Enter Buying Requirement Details